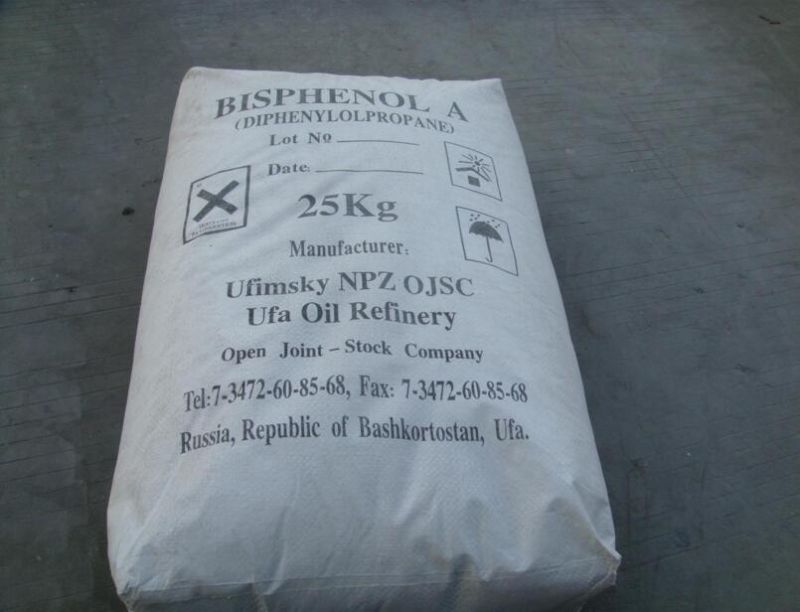

General Description:

BISPHENOL-A (BPA) is produced through an acid-catalyzed condensation reaction of phenol with acetone. BISPHENOL-A's (BPA) growth prospects remain bright, based on the high growth expected for CDs during the next few years and the emergence of new markets, such as polycarbonates for auto-glazing, that could develop after the turn of the century. Epoxies are projected to grow at a more modest 3 to 4 percent annual rate, based on continued wide acceptance in adhesives, powder coatings, and electrical and electronic applications. Bis-A used in flame retardants is forecast to grow 4 to 5 percent annually through the early years of the new century. In the environmental area, recent industry-sponsored research has found no evidence of biological effects from low-dose exposures to BPA.

| SALES SPECIFICATION | |

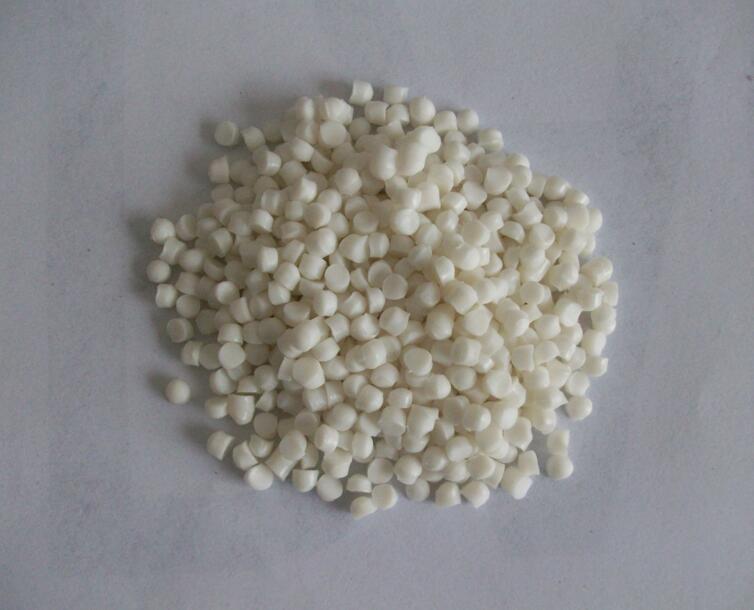

| APPEARANCE | Clean,free-flowing,dust-free prills |

| PURITY | 99.85% min |

| MELTING POINT | 156.5 C min |

| WATER | 0.1% max |

| PHENOL | 100 max(mg/kg) |

| ISOMERS | 1000 max(mg/kg) |

| BTX | 400 max(mg/kg) |

| IRON | 1 max(mg/kg) |

| MOLTEN COLOR | 20max (Pt/Co Scale) |

| ASH | 5 max(mg/kg) |

Application :

Polycarbonate resins,epoxy resins, flame retardants (mainly tetrabromobisphenol-A), unsaturated polyester, polysulfone, polyetherimide and polyarylate resins.